The culinary world is no stranger to innovation, but the emergence of plasma grilling has taken food science into uncharted territory. By harnessing the power of atmospheric ionization, researchers and avant-garde chefs are rewriting the rules of caramelization and char formation. This isn't merely another cooking gadget—it's a fundamental reimagining of how heat interacts with organic compounds at the molecular level.

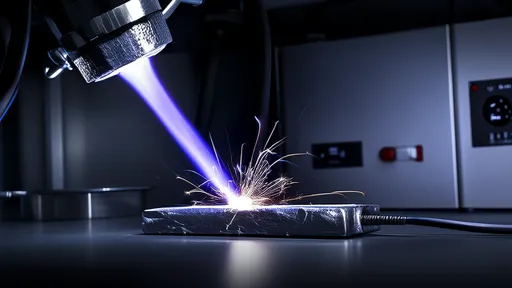

At the heart of this revolution lies the precise manipulation of ionized gas. Unlike conventional flames that blanket food with convective heat, plasma arcs deliver targeted energy to specific molecular bonds. When applied to meat surfaces, the charged particles selectively break down collagen and fats while preserving moisture content—a feat impossible with traditional infrared burners. Early adopters report achieving the perfect Maillard reaction at temperatures 30% lower than standard grilling methods, dramatically reducing carcinogenic compound formation.

The technology's implications extend beyond gourmet kitchens. Food safety engineers are particularly excited about plasma's microbial annihilation capabilities. A 2023 study published in Journal of Electrochemical Culinary Applications demonstrated complete pathogen eradication on chicken skin after just 12 seconds of exposure to modulated plasma streams. This dual functionality—simultaneous cooking and sterilization—could redefine industrial food processing standards worldwide.

However, mastering atmospheric ionization requires overcoming significant technical hurdles. The "sweet spot" between achieving perfect char and avoiding cellular disintegration varies dramatically across protein types. Salmon fillets respond best to pulsed plasma at 27 kHz, whereas beef ribeyes require sustained 42 kHz waves with intermittent cooling cycles. These discoveries emerged through trial-and-error in laboratories equipped with spectroscopic monitoring systems capable of tracking molecular changes in real-time.

Commercialization efforts are already underway, though not without controversy. Traditional pitmasters argue that plasma can't replicate the complex flavor profiles derived from wood smoke infusion. In response, Tokyo-based startup IonFlame has developed hybrid units that combine hickory smoke with ionized argon gas, creating what they term "fourth-state barbecue." Early taste tests suggest this fusion approach may satisfy purists while delivering plasma's technical advantages.

Perhaps most intriguing are the potential health benefits. The controlled ionization process appears to reduce advanced glycation end-products (AGEs) by up to 60% compared to charcoal grilling. This finding, currently under peer review, could position plasma systems as therapeutic cooking tools for diabetic and prediabetic populations. NASA has taken note, funding research into compact plasma grills for extended space missions where traditional open-flame cooking poses obvious hazards.

As with any disruptive technology, regulatory challenges loom. No existing food safety guidelines account for plasma-modified proteins, and insurance underwriters remain wary of high-voltage cooking apparatus in residential kitchens. The Institute of Electrical and Electronics Engineers (IEEE) is expected to release preliminary safety standards by Q2 2024, which may accelerate mainstream adoption.

The cultural implications run deep. From Neanderthal campfires to microwave ovens, each leap in cooking technology has reshaped human society. Plasma grilling's ability to precisely sculpt flavor compounds while minimizing harmful byproducts suggests we're entering a new era of conscious carnivory. Whether it becomes a niche tool for molecular gastronomists or evolves into the next household essential depends on solving the remaining engineering puzzles—and perhaps more importantly, winning over the taste buds of barbecue traditionalists.

Behind the laboratory doors, researchers are already pushing boundaries. Experimental protocols involve "flavor fingerprinting," where mass spectrometers identify ideal ionization patterns for replicating regional barbecue styles. Early successes include convincing simulations of Kansas City-style burnt ends using nothing but ionized air and precisely timed electrical pulses. The philosophical question arises: If plasma can perfectly mimic the chemical signature of 18-hour smoked brisket, does the cooking method still matter? Food purists and technologists will likely debate this for years to come.

Investment patterns reveal growing confidence in the sector. Venture capital firms specializing in food tech have poured $240 million into plasma cooking startups since 2021, with another $180 million expected this fiscal year. Industry analysts predict the first consumer-grade units will hit specialty stores by late 2025, priced comparably to high-end induction ranges. The true test will come when these devices transition from tech-demonstration curiosities to indispensable kitchen workhorses—a journey every major appliance category must eventually navigate.

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025

By /Jul 31, 2025